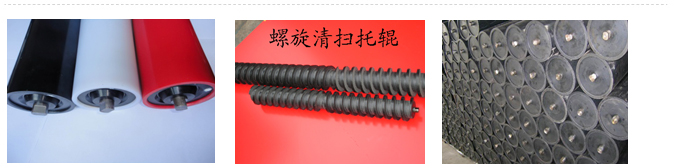

Ultra high molecular weight polyethylene (UHMWPE) roller is a kind of high-tech product which is composed of ultra high molecular weight polyethylene pipe, metal bearing, metal shaft, plastic bearing seat and sealing ring. Compared to metal roller, UHMWPE roller has many obvious advantages in operational performance.

Ultra high molecular weight polyethylene (UHMWPE) roller is a kind of high-tech product which is composed of ultra high molecular weight polyethylene pipe, metal bearing, metal shaft, plastic bearing seat and sealing ring. Compared to metal roller, UHMWPE roller has many obvious advantages in operational performance.

UHMWPE roller has good self lubrication, wear resistance and non-adhesion; therefore, materials will not adhere to or accumulate at the roller surface; and the roller surface is also difficult to scale. In addition, low friction coefficient of UHMWPE greatly reduces the friction between the roller and the tape. In case it cannot function normally, "bite" belt accidents will not occur.

Due to flexible and smooth running, low driving power consumption, UHMWPE roller can effectively reduce the belt beating, deviation, overflow, material dropping and belt wear phenomena in the conveying process. Due to small density, weight of UHMWPE roller to be generally 1/3 that of the same size metal roller, and easy to install and easy to change, small moment of inertia, low noise and extremely smooth running, UHMWPE reduces labor intensity and the amount of maintenance and has significant economic benefits. Our company’s UHMWPE roller with independent intellectual property rights uses bearings with sealing cover and adopts a series of optimization design of sealants, labyrinth slots and other combination sealing technologies among rollers, bearing seats and steel shafts, making waterproof, dustproof effects more significant.

UHMWPE roller specifications: diameter (mm) 89,102,108,127,133,152,159, length (mm) 190 ~ 2500. UHMWPE rollers are widely used in sites with large dust, strong corrosive nature and extremely harsh conditions, such as mine, coal mine, port, power plant, steel mill, cement plant, coking plant, soda and fertilizer plants and other special sites, and the rollers have extremely high cost performance.

Our company can also increase wall thickness, change the support structure to improve the bearing performance conveyed by UHMWPE roller and customize non-standard type rollers according to customer's special requirements.

Specifications of part of the UHMWPE rollers:

|

strip width |

Roller diameter |

Roller length |

strip width |

Roller diameter |

Roller length |

|

300 |

63.5,76,89 |

160,380 |

1200 |

108,133, 159

|

465,700,1400 |

|

400 |

160,250,500 |

1400 |

530,800,1600 |

||

|

500 |

200,315,600 |

1600 |

133,159,194 |

600,900,1800 |

|

|

650 |

76,89,108 |

250,380,750 |

1800 |

670,1000,2000 |

|

|

800 |

89,108,133 |

315,465,950 |

2000 |

750,1100,2000 |

|

|

1000 |

108,133 159 |

380.600,1150 |

2200 |

800,1250,2500 |

Application Notes:

1. Prevent sharp objects from carving on the roller surface;

2. It should not be used at ambient temperature above 60 ℃ ;

3. Do not use external forces to destroy the structure, then cause the firmware to be loosen.

| If interested in our products please contact us! |

Contact person: Jessie Tel:86-021-50808566 Fax:86-021-50270008 Mobile & Wechat: 13816697518 QQ:749273673

Contact person: Cheri Mobile: 18917369633 QQ:1954693891

Website:www.uhmwpe.com.cn English website: www.shuhmwpe.com

|

Shanghai Houde Rubber&Plastic Material Co., Ltd.

Shanghai Houde Rubber&Plastic Material Co., Ltd.