Ultra high molecular weight polyethylene is abbreviated as UHMWPE. UHMWPE generally refers to polyethylene whose relative molecular weight is above 1.5 million (relative molecular weight of common polyethylene is only 20,000-300,000). Due to ultra-high molecular weight, UHMWPE is a new engineering plastic with very excellent properties which the common polyethylene does not have.

Ultra high molecular weight polyethylene is abbreviated as UHMWPE. UHMWPE generally refers to polyethylene whose relative molecular weight is above 1.5 million (relative molecular weight of common polyethylene is only 20,000-300,000). Due to ultra-high molecular weight, UHMWPE is a new engineering plastic with very excellent properties which the common polyethylene does not have.

Excellent properties of UHMWPE:

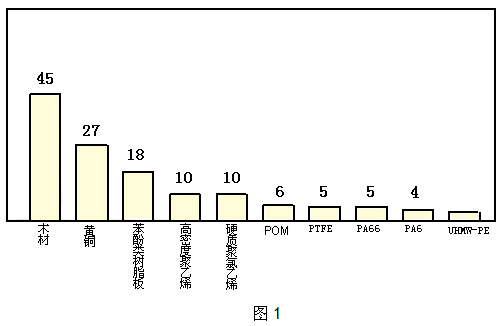

1, wear resistance:

Wear resistance of UHMWPE is the highest among the plastics, which is several times that of the carbon steel, brass (see figure 1).

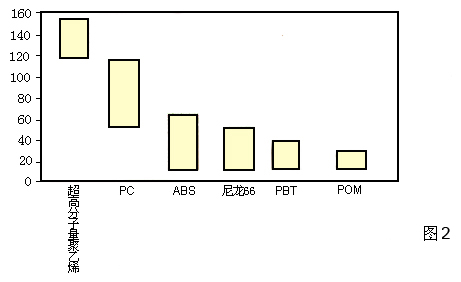

2, impact:

When the molecular weight reaches 1.5 million, the impact strength of UHMW-PE reaches the maximum value which is the highest value among the existing engineering plastics. It still has relatively high impact strength even at -70℃. See figure 2 below, comparison with the impact strengths of other engineering plastics.

3, Self lubrication:

As UHMW-PE has an extremely low friction coefficient (0.1-0.22), its self lubrication is excellent. As it can be seen from table 1 below, dynamic friction factor is 1/2 of PA66 and POM under water lubrication conditions. When UHMW-PE and steel, copper pairing are used, it is difficult to produce adhesive wear, and wear on mating parts is small. Therefore, UHMW-PE is known as the friction material with extremely ideal cost performance in the field of friction.

|

Name |

Dynamic friction factor |

||

|

UHMW-PE |

0.10~0.22 |

0.05~0.10 |

0.05~0.08 |

|

PTFE |

0.04~0.25 |

0.04~0.08 |

0.04~0.05 |

|

PA66 |

0.15~0.40 |

0.14~0.19 |

0.06~0.11 |

|

POM |

0.15~0.35 |

0.10~0.20 |

0.05~0.10 |

|

|

|

|

|

4, chemical resistance:

UHMWPE has excellent chemical resistance and can bear various corrosive media, such as, acid, alkali, salt (unstable in concentrated sulfuric acid, concentrated hydrochloric acid, concentrated nitric acid, halogenated hydrocarbon and aromatic hydrocarbon and other solvents) in a certain range of temperature and concentration, except strong oxidizing acid. UHMWPE appearance has no anomalies after dipping in other 80 kinds of organic solvents at 20℃ for 30 days, and other physical properties are almost unchanged.

5、Impact energy absorption:

UHMWPE has excellent impact energy absorption, its impact energy absorption value in all plastics is the highest. Therefore, the noise damping is very good and it has good silencing effect.

6、Low temperature resistance:

UHMWPE has excellent low temperature resistance which is the best among the existing plastics. It still has ductility at liquid helium temperatures (-269℃); therefore, it can be used as low-temperature component, cryogenic pipeline and low-temperature resistant parts of nuclear industry.

7、Healthy and non-toxicity:

UHMWPE is healthy and non-toxic, fully meets the standard of Japan Health Association and obtains acceptance of USA Ministry of Agriculture of U.S. Food and Drug Administration, and can be used for contacting the food and drugs.

8、Non-adhesion:

Surface adhesive force of UHMW-PE is very weak, its anti-adhesion ability is second to PTEF whose non--adhesion is the best in plastics. Therefore, surfaces of UHMW-PE products are not easy to stick to other materials.

9、Water absorption:

Water absorption rate of UHMW-PE is very low, which is generally less than 0.01% and 1% of PA66. Therefore, drying is not necessary before molding, and products’ dimensional changes in humid environments will not occur due to water absorption, also it will not affect the precision and wear resistance and other properties of the products (table 2).

|

Material Science |

UHMW-PE |

PA66 |

PC |

POM |

ABS |

PTFE |

|

water absorption |

<0.01 |

1.5 |

0.15 |

0.25 |

0.20-0.45 |

<0.01 |

10、Density:

As density of UHMW-P is lower than that of other engineering plastics, its products are very light (table 3)

|

Name |

PTFE |

POM |

PBT |

PC |

PA |

UHMW-PE |

|

Relative density |

2.12 |

1.41 |

1.31 |

1.20 |

1.02-1.14 |

0.945 |

11、Other properties:

Electrical property of UHMW-PE are also more excellent than that of HDPE, and resistance to environmental stress cracking resistance and fatigue resistance of UHMW-PE are better than these of HDPE.

Common property indexes of ultra high molecular weight polyethylene (table 4):

|

Classification |

Project |

CHMWPE |

ASMT |

|

Physical property |

Molecular mass / million |

200 |

D2857 |

|

Density |

0.93 |

D1505 |

|

|

Powder density |

0.46 |

D392 |

|

|

Grain size |

100~200 |

- |

|

|

Mechanical properties |

Fracture strength |

40~45 |

D638 |

|

Elongation rate |

300~400 |

D638 |

|

|

Bending modulus |

600 |

D747 |

|

|

Impact strength |

> 140 |

D250 |

|

|

Rockwell hardness |

40~60 |

D747 |

|

|

wear volume |

70 |

D1175 |

|

|

thermal property |

Melting point |

136 |

D2117 |

|

Thermal deformation |

85 |

D648 |

|

|

Coefficient of linear expansion |

1.5~2.5 |

D696 |

|

|

Thermal conductivity |

8.5 |

D177 |

|

|

Electrical properties |

Volume resistivity |

10 |

D257 |

|

Breakdown voltage |

50 |

D149 |

|

|

Dielectric constant |

2.3 |

D150 |

| If interested in our products please contact us! |

Contact person: Jessie Tel:86-021-50808566 Fax:86-021-50270008 Mobile & Wechat: 13816697518 QQ:749273673

Contact person: Cheri Mobile: 18917369633 QQ:1954693891

Website:www.uhmwpe.com.cn English website: www.shuhmwpe.com

|

Shanghai Houde Rubber&Plastic Material Co., Ltd.

Shanghai Houde Rubber&Plastic Material Co., Ltd.